Min. Order:100 Meter

Transportation:Ocean,Land

Port:Shanghai Port,Qingdao Port,Ningbo Port

$45≥100Meter

Model No.: TT-UL005

Brand: Iron Tower

Place Of Origin: China

Brand: Iron Tower

After-sales Service: Online Technical Support, Onsite Training

Warranty Service: See the corresponding standard or executed according to the contract requirements

Production Process: Calendering,forming,vulcanization

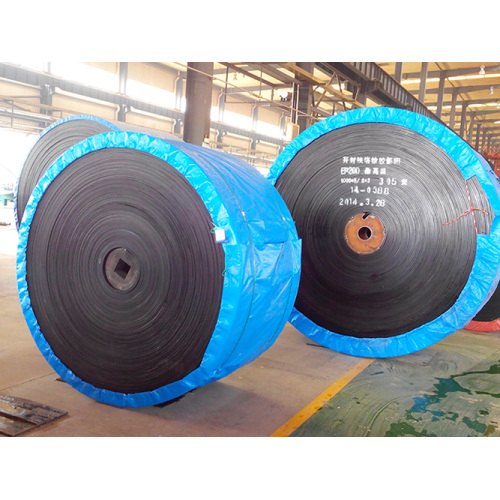

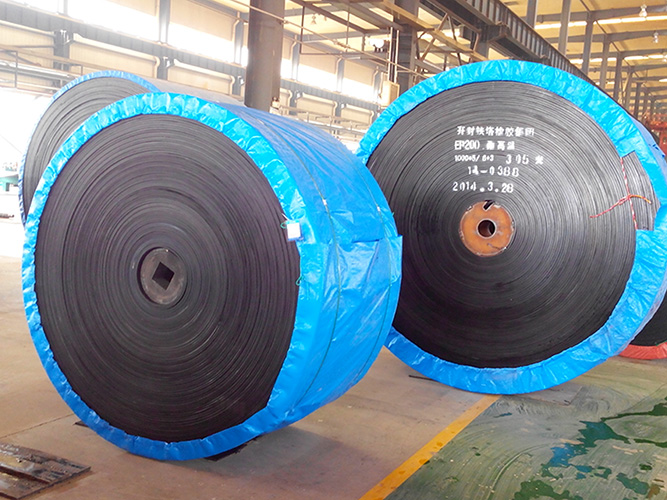

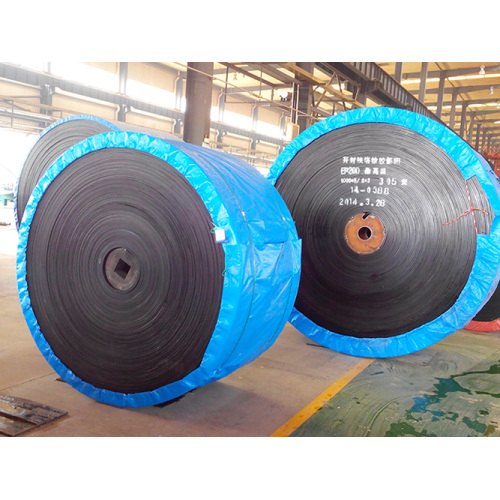

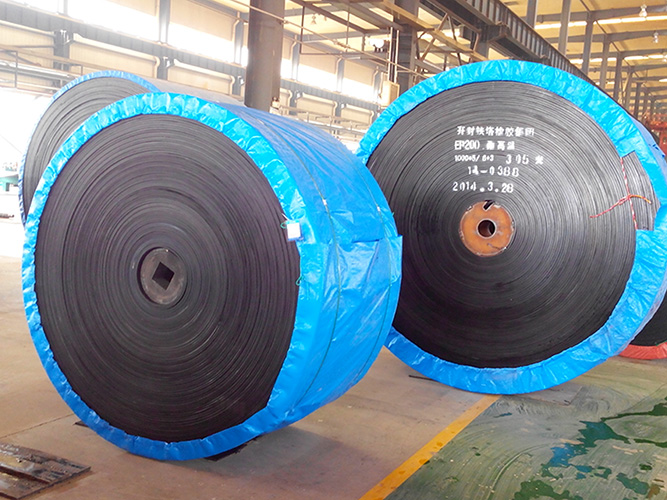

Structure: Top cover rubber+rubber fabric cord layer+bottom cover rubber+edge rubber

Shape: Roll

Canvas Layer: 3-12

Bottom Rubber Ply: 3.0mm

Top Rubber Ply: 6.0mm

Belt Width: According to customer needs

Packaging: Month supply capacity of 50000 meters

Productivity: Month supply capacity of 50000

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: Month supply capacity of 50000 meters

Certificate: ISO9001:2015

HS Code: 40101100

Port: Shanghai Port,Qingdao Port,Ningbo Port

Ultra High Strength Wear-Resistant Conveyor Belt for Industrial Material Handling

Engineered for extreme durability and consistent performance under harsh conditions, this industrial-grade conveyor belt combines exceptional tensile strength with advanced abrasion resistance. Designed to support high-volume material transport across demanding sectors such as mining, quarrying, and port logistics, it ensures minimal downtime and optimal throughput. Whether handling sharp ores, heavy aggregates, or bulk commodities like coal and grain, this solution delivers reliable operation over extended periods—making it a top choice for global industrial operations seeking long-term efficiency and cost savings.

Key Features:

Detailed Description:

This ultra-High-Strength Conveyor Belt integrates cutting-edge polymer science and robust engineering to meet the most rigorous demands of modern industry. Its multi-layer construction includes a load-bearing core composed of high-modulus fibers or steel cords, which provides excellent flexibility while resisting fatigue failure. The outer cover is made from a proprietary blend of natural and synthetic rubbers, optimized for resistance to cutting, tearing, and chemical exposure—common challenges in mining and aggregate processing environments. Additionally, the belt’s surface texture enhances grip on wet or sticky materials, reducing slippage and improving energy efficiency. With a lifespan significantly longer than standard belts, this product minimizes replacement frequency and supports sustainable operational practices.

Primary Applications:

User Feedback Highlights:

Operators in South America and Australia have reported up to 40% reduction in belt-related downtime compared to previous models. One senior engineer noted: “The wear resistance has allowed us to double our shift cycle without replacing the belt.” Another user in Europe praised its adaptability to varying weather conditions, stating: “We’ve seen no loss in traction or structural integrity even during winter months when temperatures drop below freezing.” These testimonials reflect real-world validation of the belt’s resilience, reliability, and value in diverse industrial settings.

Frequently Asked Questions:

What makes this conveyor belt different from conventional options? It offers superior tensile strength, enhanced abrasion resistance, and better temperature tolerance than standard rubber belts, making it ideal for applications where longevity and consistency are critical.

Can it be used in wet or humid environments? Yes, the belt’s formulation includes moisture-resistant additives that prevent delamination and maintain adhesion between layers, even in high-humidity or frequent washdown scenarios.

Is customization available for specific widths or lengths? Absolutely—this product supports bespoke dimensions based on client specifications, allowing seamless integration into existing systems or new installations.

How often should maintenance checks be performed? Routine inspections every 3–6 months are recommended to assess tension, alignment, and surface wear, ensuring peak performance and early detection of potential issues.