Special Use Conveyor Belt

-

Model No: TT-CC004 USD 55

-

Model No: TT-CC005 USD 55

-

Model No: TT-CC003 USD 62

-

Model No: TT-CC002 USD 66

-

Model No: TT-CC001 USD 66

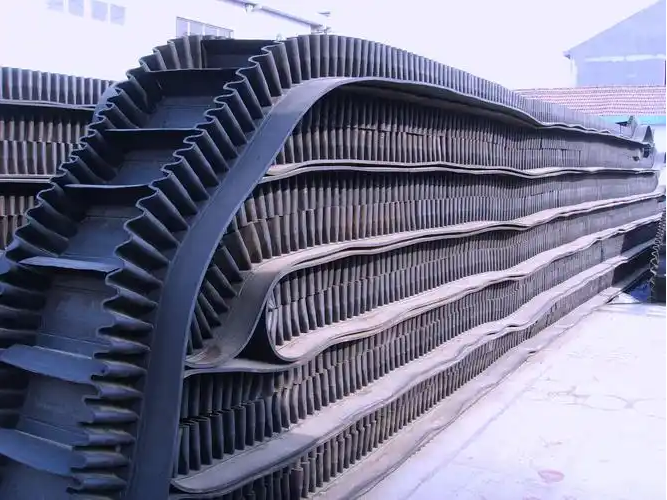

Big Obliquity Skirt Conveyor Belt

-

Model No: TT-BC004 USD 34

-

Model No: TT-BC006 USD 37

-

Model No: TT-BC005 USD 37

-

Model No: TT-BC003 USD 35

-

Model No: TT-BC002 USD 36

-

Model No: TT-BC001 USD 28

Endless Conveyor Belt

-

Model No: TT-EC005 USD 30

-

Model No: TT-EC004 USD 39

-

Model No: TT-EC003 USD 40

-

Model No: TT-EC002 USD 36

-

Model No: TT-EC001 USD 42

Special Use Conveyor Belts: Precision-Engineered Solutions for Extreme Material Handling

Defying the constraints of standard conveying systems, our Special Use Conveyor Belts represent the apex of adaptive engineering, integrating proprietary technologies to conquer vertical inclines up to 70°, operate seamlessly from -80°C to +550°C, and achieve zero-material loss in high-value processes. These purpose-built solutions combine advanced polymer science with structural innovation – from chevron-patterned anti-slip surfaces to hermetically sealed skirt designs and splice-free endless loops – delivering unmatched performance where traditional belts falter.

The series’ multi-domain superiority stems from three core technological pillars:

-

Geometric Intelligence: Chevron cleats (8-30mm) create material compartments for 45° incline stability, while corrugated sidewalls enable 70° vertical elevation without spillage.

-

Material Science Mastery: Nano-ceramic coatings resist 15g/cm³ abrasion in mining operations; FDA-grade TPU ensures hygienic food contact.

-

Structural Integrity: Steel-cord reinforced endless belts achieve ≤0.1mm thickness variance for 24/7 pharmaceutical production.

Certified to ISO 283 (tensile), EN 14973 (fire safety), and FDA 21 CFR 177.2600 (food grade), these belts solve critical challenges across industries:

-

Mining: 98% dust containment in underground coal transport via labyrinth-sealed skirt systems

-

Food Processing: <0.1µm surface roughness endless belts prevent bacterial colonization

-

Recycling: Chevron belts maintain 800TPH throughput on 40° scrap metal inclines

-

Chemicals: PTFE-lined variants withstand 98% sulfuric acid corrosion

Core Performance Matrix

Parameter Extreme Capability Industry Benchmark Incline Angle 70° (skirt systems) 30° (standard) Temp Range -80°C ~ +550°C -20°C ~ +120°C Speed Tolerance ±0.05m/s (endless) ±0.5m/s Hygiene Class EHEDG EL Class I ISO 22000

Special Use Conveyor Belt