Min. Order:100 Meter

Transportation:Air,Express

$13≥100Meter

Model No.: TT-C008

Processing Service: Moulding, Cutting

Transportation: Air,Express

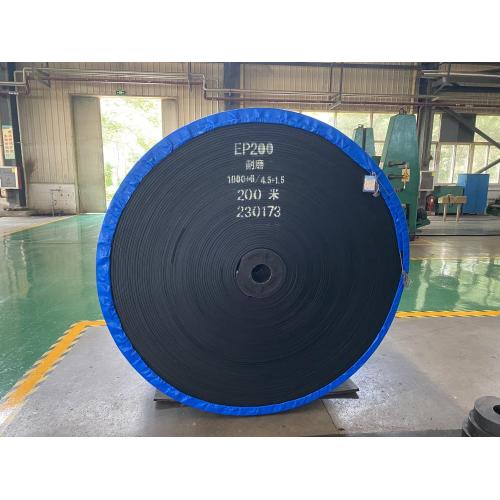

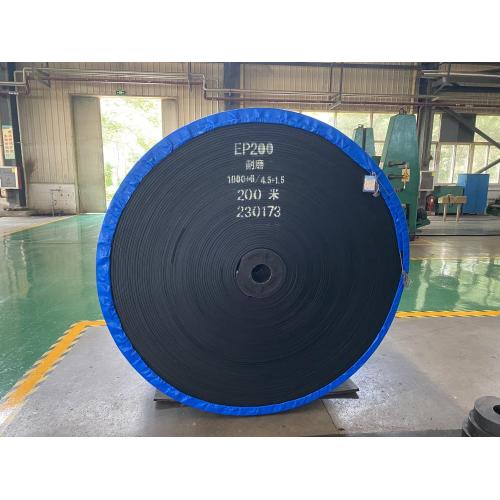

Precision EP Core Conveyor Belt for Efficient Elevating Systems

Engineered for high-performance material handling, this precision EP core conveyor belt delivers reliable operation in demanding industrial environments. Designed with a robust fabric cord structure and advanced rubber compounds, it ensures consistent power transmission, reduced downtime, and extended service life across vertical and inclined conveying applications.

Key Features:

Detailed Description:

This conveyor belt utilizes an ordinary canvas core made from interwoven synthetic fibers like nylon or polyester, which provides excellent fatigue resistance and minimal elongation over time. The layered construction allows for uniform stress distribution during operation, minimizing the risk of premature failure. The upper cover layer acts as a protective barrier against impact, chemical exposure, and mechanical wear, while the lower surface maintains smooth contact with pulleys and idlers. Edge sealing technology enhances durability at high-speed operations and prevents debris ingress—a crucial factor in food processing, mining, and manufacturing sectors.

Applications:

Ideal for bulk material transport in industries such as cement production, aggregate handling, grain processing, and packaging lines. Its lightweight yet durable design supports efficient elevation systems, including bucket elevators and vertical lifts, where energy efficiency and continuous operation are essential. Suitable for both indoor and outdoor installations due to its UV-resistant and moisture-resistant formulation.

User Feedback Highlights:

Users consistently report improved uptime, reduced maintenance costs, and enhanced product flow accuracy when compared to standard belts. Many cite the flame-retardant feature as vital for compliance with plant safety protocols, particularly in facilities handling combustible materials. The seamless integration into existing conveyor frameworks has also been praised by engineers managing automated logistics solutions.

Frequently Asked Questions:

What makes this EP core belt different from traditional rubber belts?

Unlike conventional belts that rely solely on thick rubber layers, this model incorporates a structured fabric core for better load distribution and less sagging. It offers higher tensile modulus, making it ideal for elevated conveying systems requiring precise alignment and low stretch.

Can it be customized for specific width or length requirements?

Yes, manufacturers offer tailored configurations based on operational parameters such as belt width, speed, and load capacity. Customization includes varying cover thicknesses and edge reinforcement levels to suit industry-specific needs.

Is this belt suitable for wet or corrosive environments?

The belt features a chemically resistant cover compound that resists oil, water, and mild acids. While not fully submersible, it performs reliably in humid or splash-prone conditions common in food processing and recycling plants.