Model No.: TT-C013

Brand: Iron Tower

Place Of Origin: China

Processing Service: Moulding, Cutting

Brand: Iron Tower

After-sales Service: Online Technical Support, Onsite Training

Warranty Service: See the corresponding standard or executed according to the contract requirements

Variety: Polyester (EP)Canvas Conveyor Belt

Production Process: Calendering,forming,vulcanization

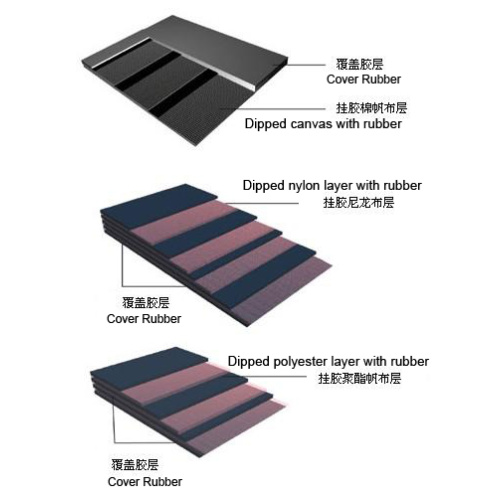

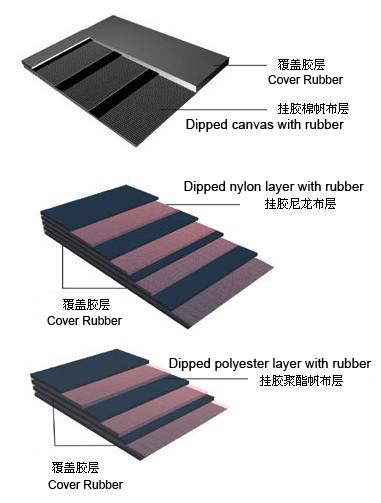

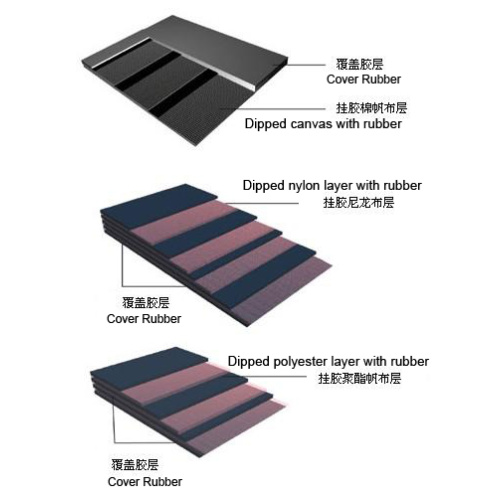

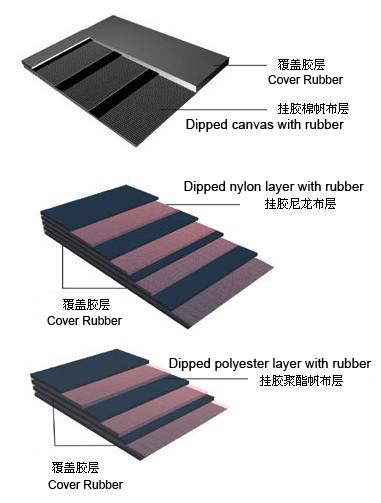

Structure: Top cover rubber+rubber fabric cord layer+bottom cover rubber+edge rubber

Shape: Roll

Packaging: UV protection packaging cloth

Productivity: Month supply capacity of 50000

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: Month supply capacity of 50000 meters

Certificate: ISO9001:2015

HS Code: 40101100

Port: Shanghai Port,Qingdao Port,Ningbo Port

The Flame-Retardant

EP Conveyor Belt stands as a premier industrial solution for high-performance material handling in safety-critical environments. Engineered with precision and built to last, this anti-static EP

Conveyor Belt combines advanced textile engineering with robust chemical resistance, making it an ideal choice for operations where fire safety, mechanical strength, and long-term reliability are non-negotiable. Known also as Fire-Resistant Polyester Canvas Belt or Safety EP Belting, the product leverages a specialized EP/NN carcass structure—where polyester yarns run longitudinally (warp) and nylon filaments are woven transversely (weft)—to deliver superior tensile strength, minimal elongation under load, and excellent fatigue resistance over extended service life. What sets this flame-retardant conveyor belt apart is its carefully balanced composition: the polyester core ensures dimensional stability and resistance to moisture absorption, while the nylon weft enhances flexibility and impact resilience. This synergy allows the belt to perform reliably under high-speed operation, heavy-duty loads, and continuous use across long conveyance distances—common requirements in mining, steel production, cement manufacturing, logistics hubs, and food processing facilities worldwide. Its surface treatment further enhances abrasion resistance and adhesion between layers, reducing internal slippage and ensuring consistent power transmission even in harsh conditions. Key features include certified flame retardancy meeting international standards such as UL 94 V-0 or EN 13823, low static charge generation that prevents spark-related hazards in explosive atmospheres, and enhanced cover rubber properties offering resistance to oils, chemicals, and UV exposure. The belt’s construction supports both standard and custom configurations, including multiple ply options, varying thicknesses, and tailored top cover textures for specific applications like coal transport, grain handling, or pharmaceutical packaging. This premium-grade EP belt excels in demanding sectors such as bulk material handling, automotive assembly lines, recycling plants, and food-grade processing units where hygiene, compliance, and uptime matter most. It’s especially suited for environments requiring Class I Division 2 or Zone 2 hazardous area certification, where flammable dusts or vapors may be present. Whether transporting ore from deep mines or conveying packaged goods through automated warehouses, the Flame-Retardant EP Belt ensures safe, efficient, and uninterrupted workflow. Users consistently praise the belt’s durability, noting reduced maintenance needs and fewer unplanned downtime incidents compared to conventional rubber belts. One operator in Australia reported a 35% improvement in belt lifespan after switching from standard cotton-ply belts to this flame-resistant EP alternative, citing better grip on wet surfaces and less heat buildup during peak shifts. Another user in Canada highlighted how the belt’s anti-static properties eliminated frequent tripping of sensitive control systems in their warehouse automation setup—a common issue previously caused by electrostatic discharge. Common questions often revolve around installation best practices, compatibility with existing pulley systems, and expected service life under different load profiles. While each application varies, general guidelines suggest using properly aligned rollers, maintaining proper tension, and inspecting regularly for wear patterns. With proper care, these belts typically last between 3 to 7 years depending on operating conditions, far exceeding the performance of traditional alternatives. In summary, the Flame-Retardant EP Conveyor Belt represents a smart investment for any industry prioritizing safety, efficiency, and operational continuity. By integrating cutting-edge materials science with proven industrial design, it delivers unmatched value—not just in performance but in peace of mind for operators managing complex, high-stakes workflows globally.