Model No.: TT-E004

Brand: TieTa Rubber

Place Of Origin: China

Processing Service: Moulding, Cutting

Strong Resistance To Oil Swelling: Complies with ASTM D471 or ISO 1817

-20 ℃ To-120 ℃: High retention rate of tensile strength

Packaging: Roll packaging,Wooden crate/wooden frame packaging,Palletizing,Special environmental packaging,Bare packaging and simple packaging

Productivity: Month supply capacity of 50000

Transportation: Land

Place of Origin: KaiFeng He Nan China

Supply Ability: 500000/㎡

Certificate: ISO9001,Conformité Européene

HS Code: 4010120000

Port: Qing Dao Port, Tian Jin Port,Ning Bo Port

Good Quality Oil Resistant NN/

EP Conveyor Belt – Durable, Reliable & Engineered for Demanding Environments This high-performance oil-resistant

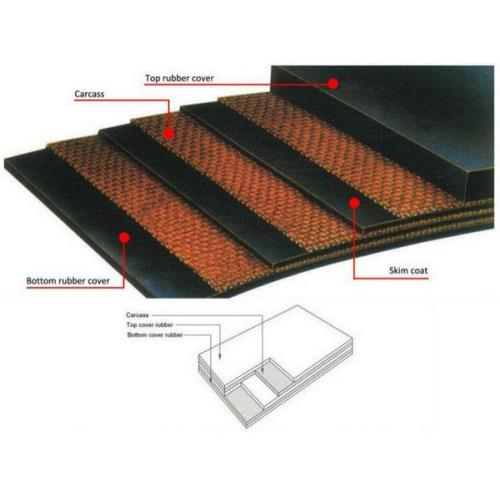

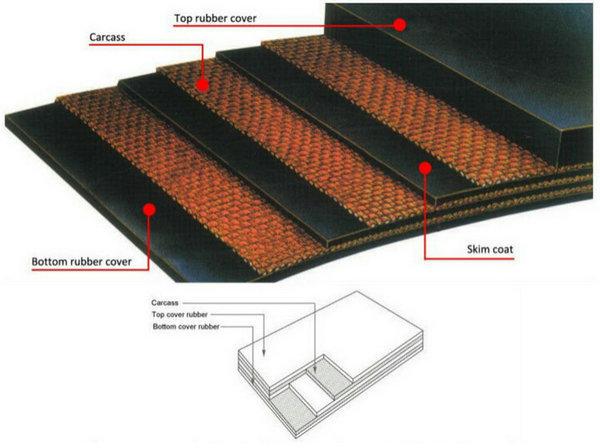

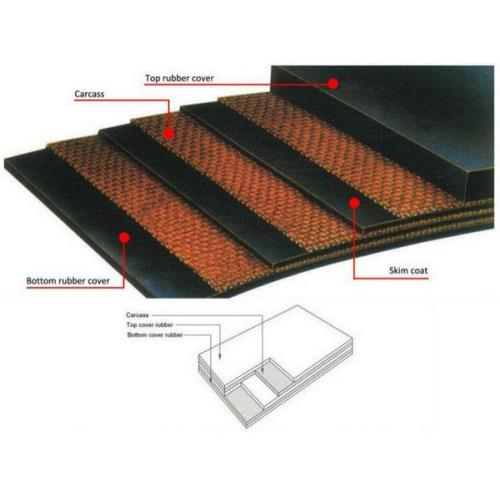

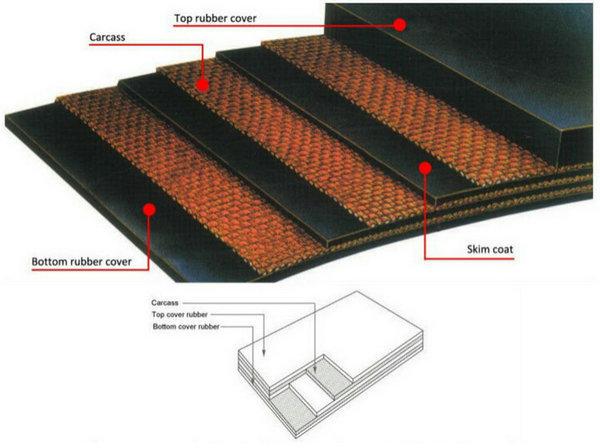

Conveyor Belt is specifically designed for industrial applications where exposure to oils, fuels, and chemical substances is common. Whether you're handling automotive parts, food processing materials, or heavy machinery components, this belt delivers consistent performance under challenging conditions. Its robust construction combines advanced core materials with premium nitrile rubber cover layers, making it a top choice for engineers, maintenance managers, and production supervisors seeking long-term durability and minimal downtime. Key Features: - Advanced Core Fabric: Available in cotton canvas, nylon, or polyester options—each offering distinct advantages in strength, flexibility, and dimensional stability. - Premium Nitrile Rubber Cover: High acrylonitrile content ensures excellent resistance to oil degradation, abrasion, and environmental aging. - Enhanced Load Capacity: Designed for both light-duty and medium-load operations across diverse industries. - Excellent Flexibility and Shock Absorption: Reduces stress on drive systems while maintaining smooth operation over extended periods. - Low Maintenance Requirements: Withstands repeated flexing and temperature variations without cracking or delamination. Detailed Description: The foundation of this oil-resistant conveyor belt lies in its multi-layered structure. The core fabric—ranging from cotton-based for cost-effective solutions to high-strength polyester or nylon for demanding environments—provides the necessary tensile strength and fatigue resistance. For instance, nylon canvas offers superior wear resistance ideal for continuous motion systems, while polyester reinforcement ensures minimal elongation under load, crucial for precision-driven manufacturing lines. The outer cover, typically made from nitrile butadiene rubber (NBR), serves as the first line of defense against hydrocarbons, lubricants, and solvents. This synthetic elastomer exhibits exceptional resilience when exposed to mineral oils, hydraulic fluids, and even some alcohols—a critical feature for applications in petrochemical plants, automotive assembly lines, or food processing units where contamination risks are high. Unlike standard rubber belts that degrade quickly upon contact with oils, this product maintains structural integrity, reducing replacement frequency and associated operational costs. Additionally, the belt’s surface texture can be customized—smooth for clean goods transport or grooved for improved grip on oily or uneven surfaces. It complies with international safety standards for mechanical handling equipment, ensuring compliance with global regulations regarding material handling in hazardous environments. Ideal Use Cases: This conveyor belt excels in sectors such as automotive manufacturing, metal fabrication, packaging, food processing, and chemical distribution. It is particularly effective in environments involving engine oil transfer, lubricant application, or transportation of greasy components. Its ability to resist both physical wear and chemical attack makes it suitable for use in automated production lines, warehouse logistics systems, and outdoor conveyor setups subjected to fluctuating weather conditions. Customer Feedback: Users consistently praise the belt's reliability during prolonged use in harsh settings. One engineer noted, “After switching to this oil-resistant model, our conveyor system experienced fewer breakdowns due to belt deterioration.” Another user highlighted its ease of installation and compatibility with existing pulley systems, emphasizing how it reduced labor hours spent on routine maintenance. Frequently Asked Questions: What makes this belt different from regular conveyor belts? Unlike conventional rubber belts, this one uses specialized nitrile rubber compounds engineered to resist oil absorption and chemical degradation—ensuring longer service life and better performance in contaminated environments. Can it handle heavy loads? Yes, especially when constructed with polyester or nylon core fabrics, which offer enhanced tensile strength and resistance to stretching under sustained weight. Is it suitable for food-grade applications? While not explicitly certified for direct food contact, its non-toxic composition and easy cleaning properties make it appropriate for indirect food handling scenarios—provided local hygiene guidelines are followed. How often should I inspect or replace the belt? Routine checks every 3–6 months are recommended depending on usage intensity. With proper care, this belt typically lasts 2–5 years in typical industrial conditions.