Model No.: TT-B004

Brand: TieTa Rubber

Place Of Origin: China

Processing Service: Moulding, Cutting

High Tensile Strength: Excellent Abrasion Resistance

High Impact Resistance: Good Flexibility & Troughability

Packaging: Roll packaging,Wooden crate/wooden frame packaging,Palletizing,Special environmental packaging,Bare

Productivity: Month supply capacity of 50000

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 500000/㎡

Certificate: ISO9001 Conformité Européenne

HS Code: 40101100

Port: Qing Dao Port,Tian Jin Port,Ning bo Port

Nylon Conveyor Belt: High-Performance Solution for Industrial Material Handling This nylon

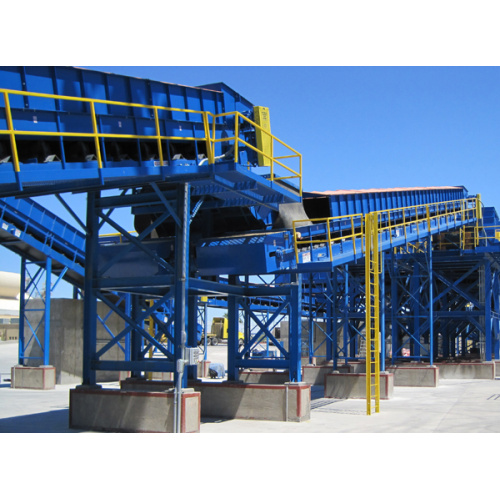

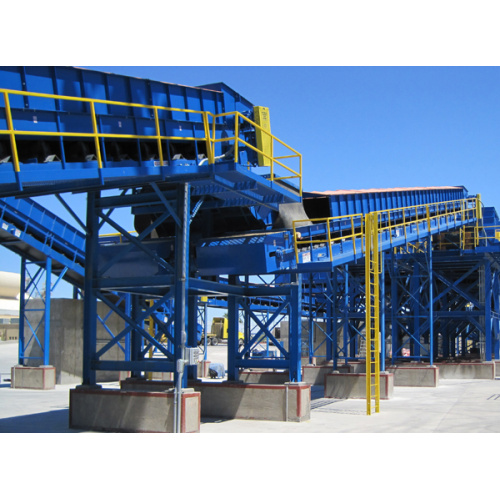

Conveyor Belt is engineered for durability, efficiency, and reliability in demanding industrial environments. Designed with advanced polymer technology, it delivers consistent performance under high load conditions while maintaining flexibility and minimal elongation over time. Ideal for medium to long-distance transportation systems, this belt supports high-speed operations without compromising safety or throughput—making it a top choice for manufacturers seeking optimized logistics solutions. Key Features: - Exceptional tensile strength and impact resistance for heavy-duty applications - Low stretch during operation ensures stable tension and reduced maintenance - Superior flexibility allows smooth curvature and troughing capabilities - Excellent abrasion resistance extends service life in abrasive material handling - Lightweight design reduces energy consumption compared to traditional belts Detailed Description: The nylon conveyor belt combines the best properties of synthetic fibers and reinforced polymers to create a durable yet lightweight solution for modern industrial conveyance. Its molecular structure provides outstanding elasticity, enabling it to absorb shocks from sudden load changes without deformation—a critical factor in automated production lines. Unlike rubber or PVC alternatives, this belt maintains dimensional stability even at elevated temperatures and under continuous stress, ensuring precise alignment and reduced downtime. The surface finish enhances grip on various materials—from bulk powders to packaged goods—while minimizing friction-related wear. With a low coefficient of thermal expansion, it performs consistently across temperature variations, making it suitable for both indoor and semi-outdoor settings such as warehouses, food processing plants, and mining facilities. Ideal Applications: - Bulk material transport in cement, grain, and chemical industries - High-speed packaging lines in food and beverage manufacturing - Mining and quarry operations requiring ruggedized conveyor systems - Automotive assembly plants where precision and speed are essential - Recycling centers handling mixed waste streams with variable densities User Feedback: Customers praise its resilience under constant use and ease of integration into existing conveyor setups. Many report a 30% reduction in belt replacements due to improved longevity and fewer misalignment issues. Users also highlight how the belt’s quiet operation contributes to better working conditions in enclosed spaces. Frequently Asked Questions: What makes this

Nylon Belt different from rubber or

steel cord belts? Unlike rubber belts that degrade faster under UV exposure or extreme temperatures, nylon offers superior environmental resistance and lower weight. Compared to steel cord belts, it requires less maintenance and poses no risk of corrosion or metal fatigue. Is it suitable for food-grade environments? Yes, when manufactured using FDA-compliant materials, it meets hygiene standards for direct contact with consumable goods—ideal for bakeries, dairy processors, and pharmaceutical units. How does it perform at high speeds? Engineered for speeds up to 5 meters per second, it maintains tension integrity and minimizes vibration, ensuring smooth operation even in fast-paced production cycles.