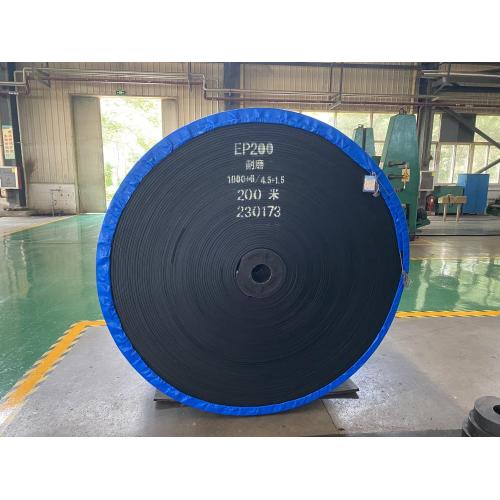

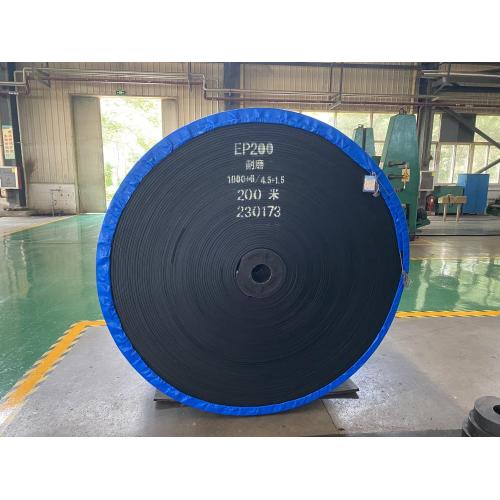

Transportation: Ocean,Land

ST/S1250 Rubber

Conveyor Belt – High-Performance, Flame-Retardant Solution for Industrial Material Handling This advanced ST/S1250 rubber conveyor belt is engineered for heavy-duty industrial applications where durability, safety, and continuous operation are critical. Designed with a flame-retardant compound and reinforced with high-tensile steel cords, it delivers superior resistance to abrasion, impact, and environmental stressors—making it ideal for demanding sectors such as mining, construction, and logistics. The belt’s robust structure ensures reliable performance under extreme conditions while maintaining compliance with international safety standards. Key Features: - Flame-retardant rubber compound meets stringent fire safety regulations - Steel-cord reinforcement provides exceptional tensile strength and elongation resistance - Abrasion-resistant surface minimizes wear from constant contact with rollers and bulk materials - Enhanced flexibility in low temperatures and thermal stability in high-heat environments - Chemical and moisture resistance for use in wet or chemically aggressive settings Detailed Description: The ST/S1250 conveyor belt integrates a premium synthetic rubber matrix with multiple layers of woven polyester fabric and a central

steel cord core. This multi-layered construction not only increases load-bearing capacity but also reduces the risk of belt failure due to fatigue or misalignment. Unlike standard rubber belts, this model undergoes specialized curing processes that improve molecular bonding between the rubber and reinforcing elements, resulting in longer service life and reduced downtime. Its flame-retardant properties are certified to prevent ignition and slow flame spread—critical for underground mining operations or confined industrial spaces where fire hazards must be minimized. Additionally, the belt maintains consistent performance across varying climates, from arctic cold to desert heat, ensuring uninterrupted material transport regardless of location. Ideal Use Cases: In the mining sector, this conveyor system efficiently moves raw ores like copper, iron, or coal from extraction zones to processing units over long distances, even through tunnels or steep inclines. For aggregate handling in cement plants or quarries, its high-strength design supports continuous flow of sand, gravel, and crushed stone without deformation or slippage. In large-scale distribution centers, it serves as an automated solution for transporting palletized goods, reducing manual labor and enhancing throughput efficiency. Whether used in open-air facilities or enclosed warehouses, the ST/S1250 excels in both vertical and horizontal conveying systems. User Feedback: Operators in mining operations have reported up to 30% longer belt life compared to conventional models, particularly when transporting abrasive materials such as limestone or ore fines. Logistics managers appreciate the belt’s quiet operation and minimal maintenance needs, which contribute to smoother warehouse workflows. Maintenance teams highlight its ease of inspection and repair, thanks to clearly defined layer interfaces and durable edge protection. Frequently Asked Questions: What makes the ST/S1250 different from other steel-cord belts? It combines enhanced flame retardancy with optimized tensile strength, making it suitable for both hazardous and high-load environments. Can it handle temperature extremes? Yes, it functions reliably between -20°C and +70°C, though special formulations may be needed for more extreme conditions. Is it compatible with existing conveyor systems? Its modular design allows for seamless integration into most standard belt conveyors, including those using take-up mechanisms or tensioning devices. How often should inspections be performed? Regular checks every 4–6 months are recommended to monitor wear patterns, especially at splice points and roller contact areas. This product is tailored for global industries seeking dependable, safe, and efficient bulk material transportation solutions—offering a balance of innovation, resilience, and operational excellence.