Transportation: Ocean,Land

St3500

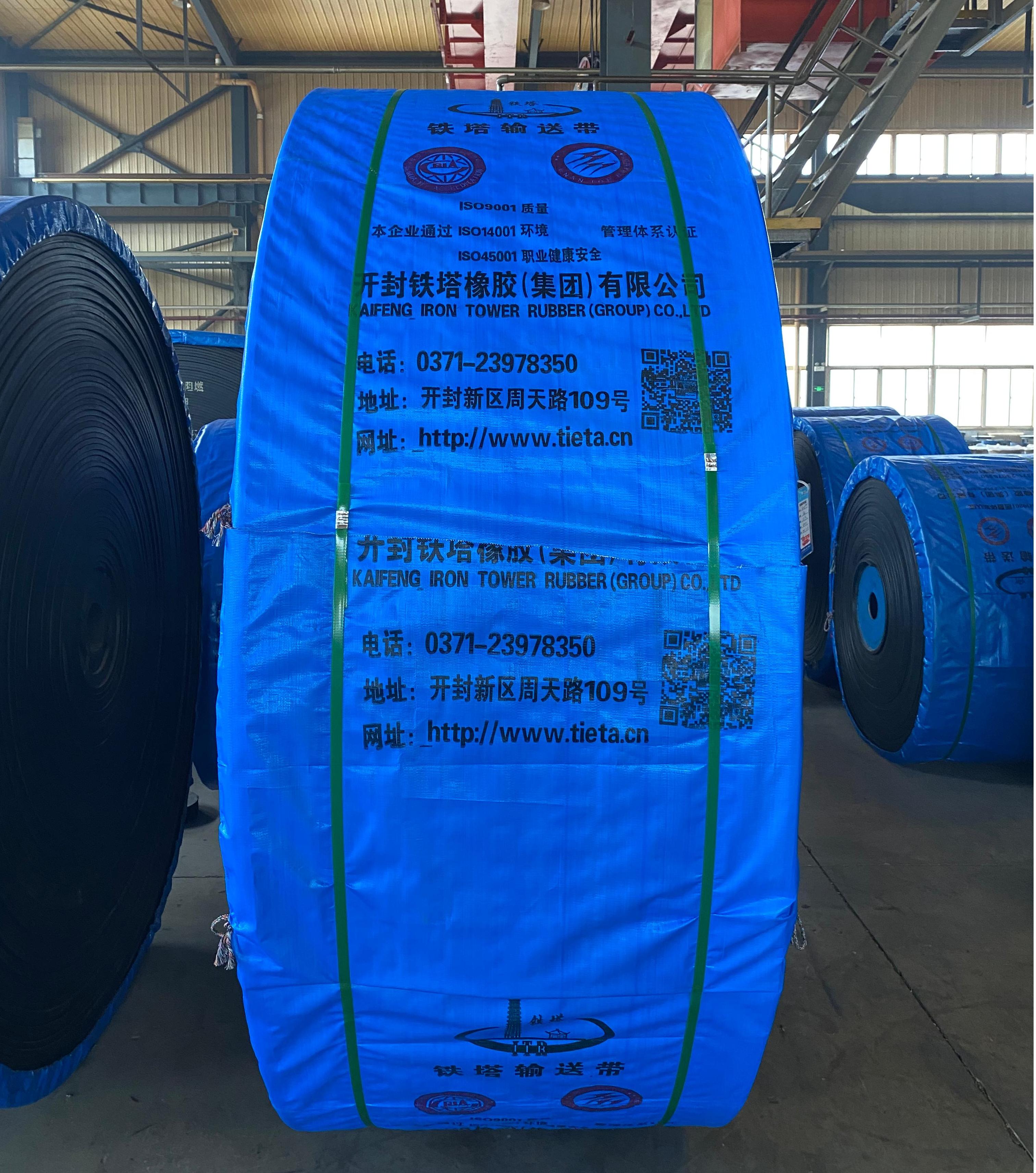

Steel Cord Conveyor Belt – High-Performance Solution for Heavy-Duty Industrial Material Handling The St3500

steel cord Conveyor Belt is a premium-grade, fire-resistant conveyor system engineered for maximum durability and operational efficiency in the most demanding environments. Designed specifically for coal mining operations but equally effective across quarries, recycling plants, and heavy manufacturing facilities, this belt delivers consistent performance under extreme loads, abrasive conditions, and challenging inclines. With its advanced steel cord tensile structure and specialized rubber compounds, it meets international safety standards while ensuring long-term reliability and minimal maintenance downtime. Key Features: This industrial-grade conveyor belt features a high-strength TC-70/TC110 steel cord carcass rated at 3500 N/mm, offering superior tensile strength and resistance to elongation over time. The belt’s surface incorporates a 15mm chevron profile combined with Y-shaped cleats (6mm–20mm) that provide excellent anti-slip properties, especially when conveying bulk materials on steep gradients. Its herringbone tread pattern enhances grip and reduces material spillage, improving transport efficiency. Constructed from flame-retardant rubber compounds compliant with global mining safety regulations—such as those set by MSHA and ATEX—the St3500 ensures safe operation even in explosive or high-risk zones. Additionally, the splayed design minimizes edge wear and internal stress, significantly extending service life compared to conventional belts. Detailed Description: Manufactured using top-tier synthetic rubbers and reinforced with precision-engineered steel cords, the St3500 offers an ideal balance of flexibility and resilience. Unlike standard conveyor belts that degrade quickly under continuous strain, this model maintains structural integrity through repeated flexing and exposure to harsh elements like dust, moisture, and temperature fluctuations. The fireproof nature of the belt makes it suitable for underground applications where ignition risks must be minimized. Furthermore, its compatibility with various conveyor frame systems allows for easy integration into existing infrastructure without costly modifications. Whether used in fixed installations or mobile setups, the St3500 adapts seamlessly to diverse operational needs while maintaining optimal tension control and alignment stability. Application Scenarios: Ideal for underground coal mines requiring robust, reliable material transport solutions, the St3500 also excels in open-pit mining, aggregate processing, cement production, and waste management industries. It performs exceptionally well in environments involving coarse, abrasive materials such as crushed stone, ore, and recycled metals. Because of its ability to handle high-capacity throughput without excessive wear, it supports continuous operation in logistics hubs and industrial plants worldwide. This belt is particularly favored in regions with strict occupational health and safety requirements due to its compliance with international fire-resistance standards and low emission profiles. User Reviews: Operators and facility managers globally report significant improvements in uptime and reduced maintenance costs after switching to the St3500. Users highlight its ease of installation and replacement—thanks to standardized dimensions and modular construction—as a major advantage over competing models. Many note fewer belt failures during peak load periods and improved operator confidence due to the belt's predictable behavior under varying conditions. Long-term users emphasize how the belt’s resistance to fatigue and abrasion translates into substantial cost savings over several years of service. Frequently Asked Questions: What makes the St3500 different from other steel cord belts? It combines enhanced fire resistance, optimized cleat geometry for better traction, and a durable rubber formulation tailored for extended service life in aggressive environments. Is it suitable for inclined conveyors? Yes—it performs exceptionally well on inclines up to 30 degrees thanks to its chevron pattern and cleated design that prevents slippage. How does it perform in high-dust or wet conditions? Its closed-cell rubber composition resists moisture absorption and particle penetration, reducing degradation and maintaining grip even in humid or dusty settings. Can it be integrated into existing conveyor systems? Absolutely—it fits standard roller configurations and can be retrofitted with minimal adjustments, making it a versatile upgrade option for aging infrastructure.