Model No.: TT-L012

Brand: IRON TOWER

Place Of Origin: China

Processing Service: Moulding, Cutting

Maximum Nominal Diameter Of Steel Wire R: 8.1

Wire Rope Spacing: 15

Upper Cover Adhesive Thickness: 8

Lower Cover Adhesive Thickness: 8

Longitudinal Tensile Strength: 3150N/MM

Packaging: Based on customer needs

Productivity: 50000meter/month

Transportation: Ocean

Place of Origin: China

Supply Ability: 50000meter/month

Certificate: ISO9001

HS Code: 4001000

Port: Qingdao Port,上海港,上海港

Industrial

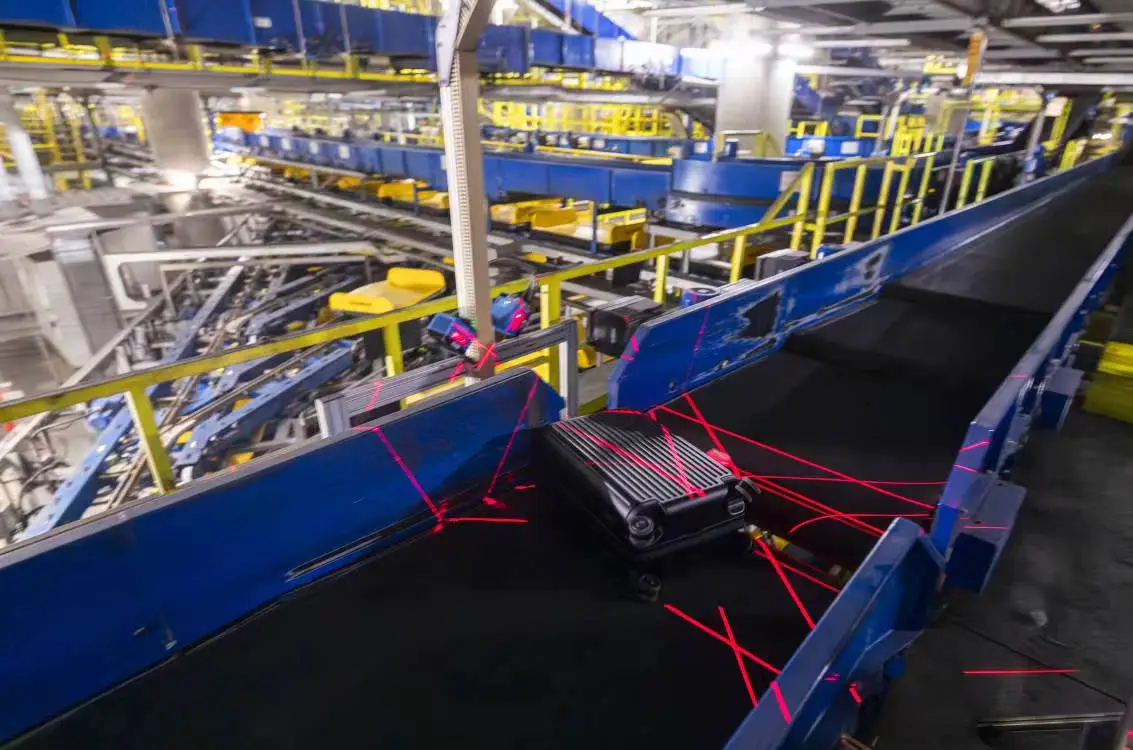

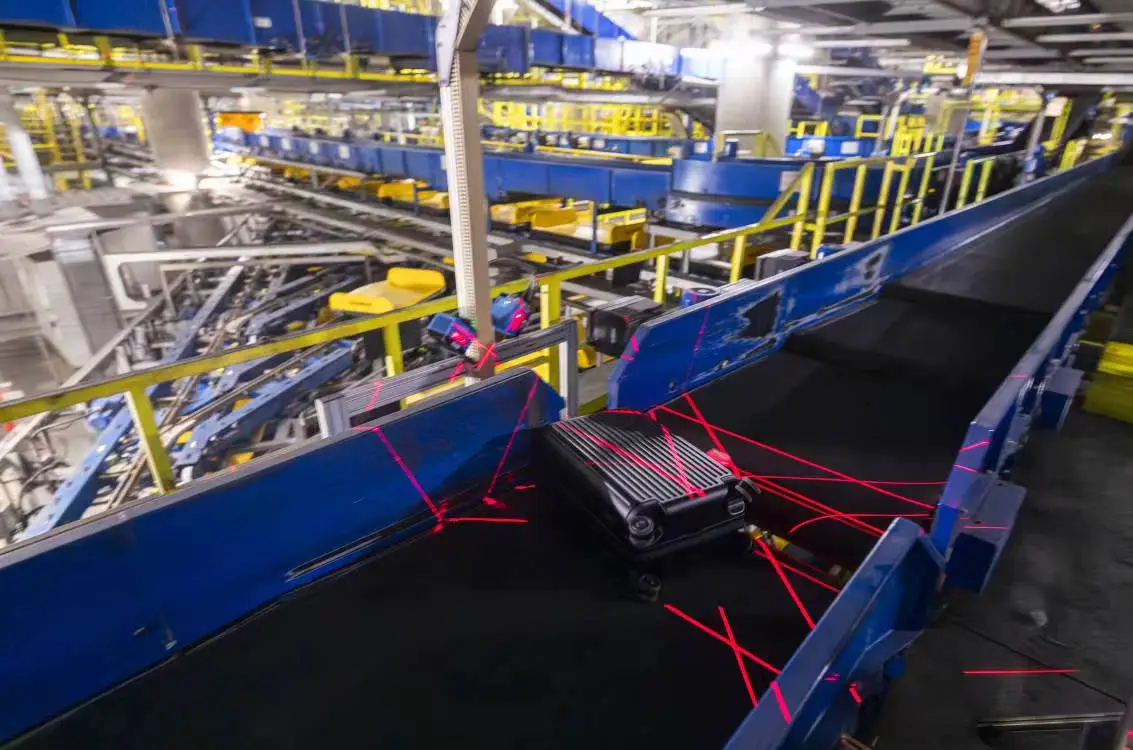

steel cord Conveying Belt – High-Performance Solution for Heavy-Duty Material Handling Across Global Industries This advanced industrial steel cord conveying belt is engineered to deliver exceptional durability, strength, and reliability in demanding environments. Designed for continuous operation under extreme loads and harsh conditions, it serves as a cornerstone of efficient logistics systems in mining, metallurgy, power generation, port operations, and beyond. With compliance to the GB/T 9770-2013 standard, this

Conveyor Belt ensures superior tensile resistance, minimal elongation under stress, excellent abrasion resistance, and strong adhesion between layers—critical attributes for long-term performance and safety. Key Features: - Reinforced with high-tensile steel cords for maximum load-bearing capacity - Heat-resistant cover rubber suitable for elevated temperatures up to 150°C - Anti-static and flame-retardant properties for enhanced workplace safety - Low-stretch design minimizes slippage and improves alignment accuracy - Customizable width, length, and ply configurations based on operational needs - Enhanced splice integrity for seamless integration into existing conveyor systems Detailed Description: The

Steel Cord Conveyor Belt combines modern material science with proven engineering principles to create a robust solution for bulk material transport. Unlike traditional fabric belts, its internal steel wire reinforcement provides significantly higher tensile strength while maintaining flexibility. This allows for longer spans without intermediate supports, reducing maintenance costs and increasing throughput efficiency. The outer rubber layers are formulated with wear-resistant compounds that resist cutting, impact, and chemical exposure—ideal for transporting abrasive materials like coal, ore, slag, and aggregates. Additionally, the belt’s construction adheres strictly to international quality benchmarks, ensuring consistent performance across diverse global applications. Application Scenarios: In coal mining operations—both underground and open-pit—the belt efficiently moves large volumes of extracted coal from extraction zones to processing plants or stockpiles, supporting uninterrupted production cycles. In mineral extraction sites, whether metallic (iron, copper, aluminum) or non-metallic (limestone, phosphate), it facilitates the movement of raw ore to beneficiation facilities and tailings to disposal areas. At maritime terminals, this conveyor system streamlines the handling of bulk commodities such as iron ore, coal, grain, and cement, enabling faster turnaround times for ships and trucks. Within steel mills and smelters, it transports sintered ores, coke, and furnace residues through high-temperature zones where conventional belts would fail. Power stations rely on these belts to feed pulverized coal into boilers, ensuring stable energy output even during peak demand periods. User Testimonials: Operators in Australia’s Pilbara region praised the belt's resilience in arid conditions, noting reduced downtime despite daily exposure to dust and temperature fluctuations. A European port authority reported a 30% increase in cargo handling speed after upgrading to this steel-reinforced system. Meanwhile, a South American mining company highlighted improved safety metrics due to the belt’s static-dissipative surface and low-maintenance design. Frequently Asked Questions: What makes steel cord conveyor belts better than fabric belts? Steel cord belts offer higher tensile strength, lower elongation, and greater resistance to fatigue, making them ideal for heavy-duty, long-distance applications where reliability is paramount. Can this belt operate in high-temperature environments? Yes, the cover rubber is specifically formulated to withstand temperatures up to 150°C, making it suitable for use in steelmaking processes and other thermal operations. Is it compatible with existing conveyor systems? Absolutely. These belts can be integrated into most standard conveyor setups with proper tensioning and pulley alignment, often requiring only minor adjustments. How does the GB/T 9770-2013 standard ensure quality? This Chinese national standard outlines strict testing protocols for tensile strength, elongation at break, flexural endurance, and adhesion properties—ensuring every batch meets rigorous performance criteria before deployment.