Core Technical Advantages

| Feature | Benefit |

|---|---|

| Solid woven PVC/PVG coating | Prevents belt delamination in humid conditions |

| Anti-static conductive layer | Dissipates <10⁹Ω surface resistance |

| 3D-reinforced edge design | Withstands 300% higher side impact vs. conventional belts |

Underground coal mines (methane-rich atmospheres)

Power plant coal handling systems

Chemical plants transporting flammable powders

Our product range spans Grade K (≤18MPa) to Grade L (≤25MPa) tensile strength options, with optional ceramic lagging for inclined conveyors exceeding 30° gradients. The belts' <0.8mm/m surface wear rate ensures 2-3x longer service life than ISO 283-compliant alternatives.

Enhance Your Safety Protocol

Explore our underground mining conveyor solutions featuring integrated spark detection sensors. For complete fire prevention systems, pair with our industrial fire safety equipment including explosion-proof motors and infrared overheating alarms.

✅ Dual certification: MSHA (US) and DGMS (India) approved

✅ Temperature resilience: Operates from -40°C to +120°C

✅ Eco-compliant: Halogen-free formulations meet EU RoHS

For operations requiring ATEX Zone 1 compliance, we offer conductive versions with <10⁶Ω volume resistance. The integrated tracking guide strips eliminate belt misalignment incidents, reducing unplanned downtime by 40% in coal processing plants.

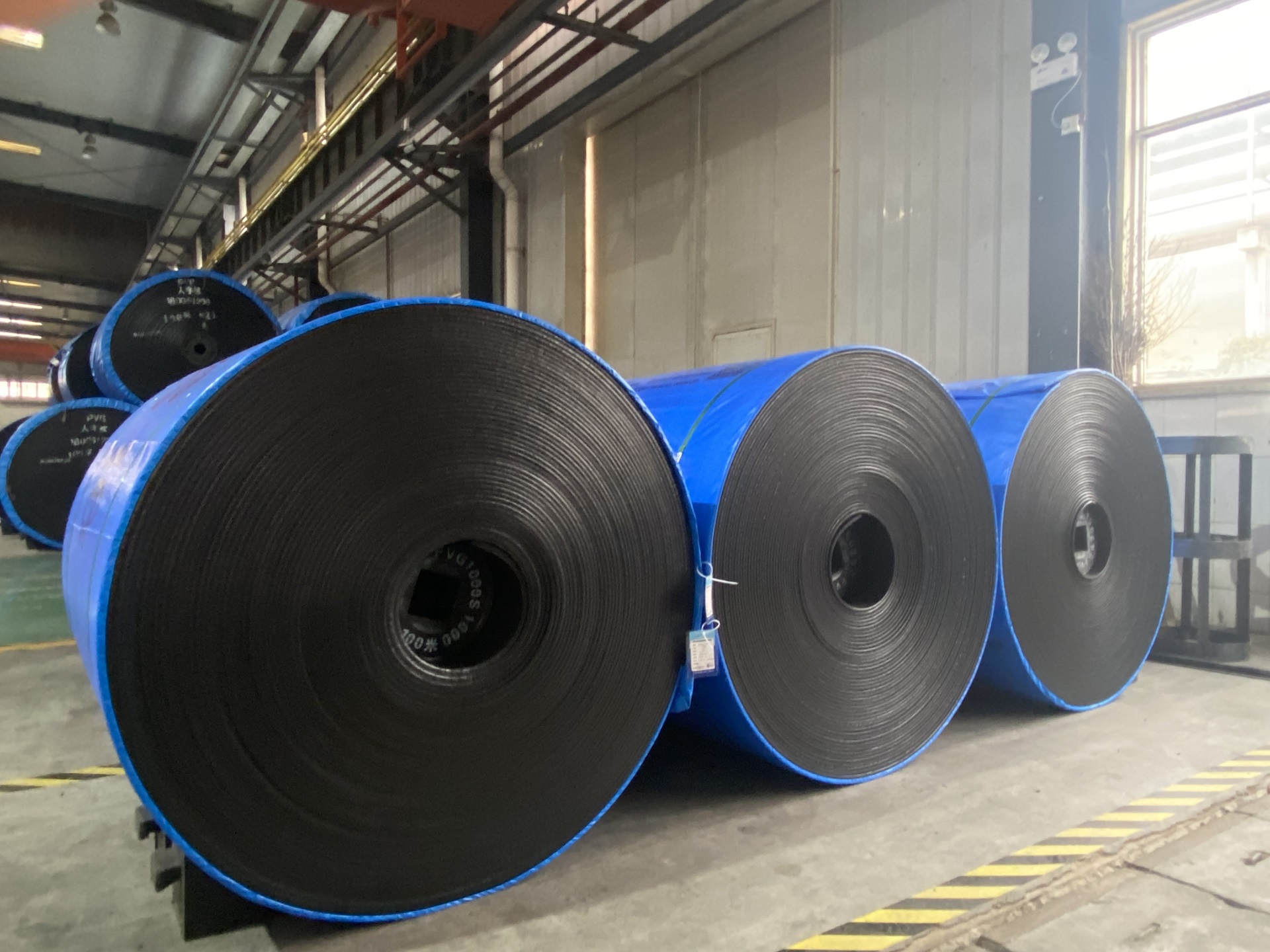

Solid Woven Flame Resistance Conveyor Belt

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.