Ultra-high Molecular Weight Polyethylene Idler Roller

(Total 5 Products)

-

Ultra-high molecular weight polyethylene idler roller

Contact Now

-

-

-

-

-

Unit Price:5~20USD

Min. Order:10 Piece/Pieces

Transportation:Ocean,Land

Place of Origin:China

Ultra-high molecular weight polyethylene idler roller

Kangfu Iron Tower Rubber (Group) Co., Ltd.'s ultra-high molecular polyethylene idler rollers are a new generation upgrade accessory for belt conveyors. They feature an ultra-high molecular...

-

Unit Price:USD 500 / Piece/Pieces

Min. Order:100 Piece/Pieces

Transportation:Ocean,Land

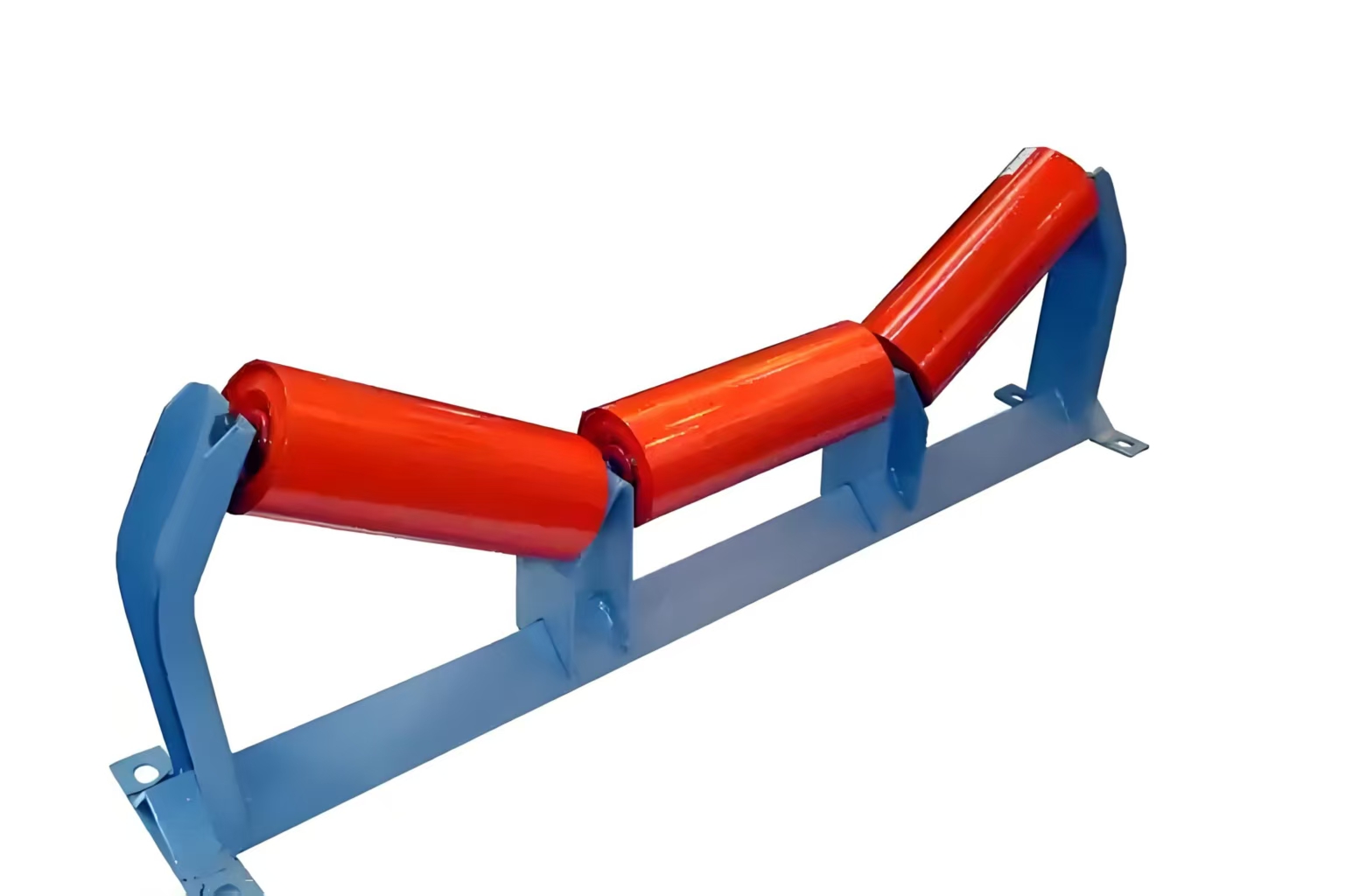

Slot-type idler roller Kaifeng Taita Rubber (Group) Co., Ltd. has been deeply engaged in the field of conveying equipment for over several decades. They meticulously create high-quality trough-type idlers, which are the core load-bearing components...

-

Unit Price:5~20USD

Min. Order:50 Piece/Pieces

Transportation:Ocean,Land

Parallel idler rollers

The product is designed with a single or double parallel structure. The roller body is made of high-quality seamless steel tubes and high-performance wear-resistant materials, combined with precise bearings and dust-proof...

-

Unit Price:5~20USD

Min. Order:20 Piece/Pieces

Transportation:Ocean,Land

Place of Origin:China

Impact-resistant Idler Roller The buffer idler produced by Kaifeng Tie Ta Rubber (Group) Co., Ltd. is a core protective component in the receiving area of belt conveyors. The product features a wear-resistant high-molecular rubber-coated roller...

-

Unit Price:5~20USD

Min. Order:20 Piece/Pieces

Transportation:Ocean,Land

Place of Origin:China

Comb-shaped idler roller Kaifeng Iron Tower Rubber (Group) Co., Ltd.'s comb-shaped idler is a specialized cleaning and protective component for the return section of belt conveyors. The product features a high-strength alloy steel drum body, a...

The Ultra-high Molecular Weight Polyethylene Idler Roller is made with ultra-high molecular weight polyethylene (UHMW-PE) with a molecular weight of over 3 million as its core material. The roller body is combined with bearings, sealing components and shafts to form a sealing structure that can isolate contaminants and has excellent protective properties. The product is classified by function into trough-shaped, parallel, self-aligning, buffering and other types, suitable for different conveying requirements. Its material features wear resistance (7 times that of steel), corrosion resistance, self-lubrication and non-stickiness to materials, and weighs only 1/3 of the steel idler roller of the same specification. It is widely used in mining, coal mines, ports, power, chemical, cement and other industrial environments with high dust and strong corrosiveness. It can extend the belt's lifespan, reduce energy consumption and noise, and is easy to install and maintain. It is an ideal upgraded replacement product for traditional metal idler rollers.