Abrasive Resistant Conveyor Belt

(Total 5 Products)-

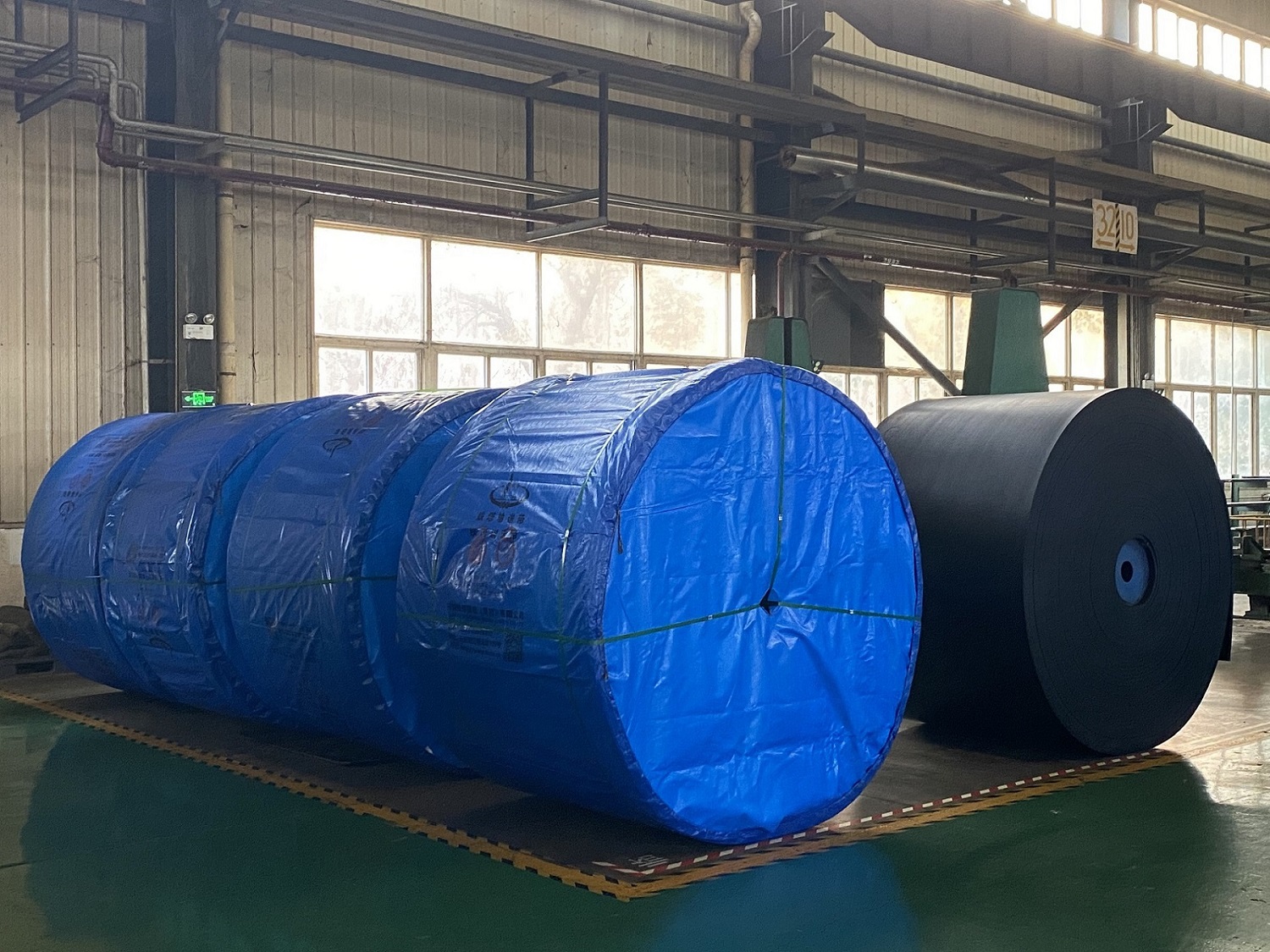

Unit Price:USD 12 / MeterBrand:ieTa RubberMin. Order:100 MeterModel No:TT-F001Transportation:Ocean,LandPackaging:Roll packaging,Wooden crate/wooden frame packaging,Palletizing,Special environmental packaging,Bare packaging and simple packagingSupply Ability:500000/㎡Place of Origin:KaiFeng He Nan ChinaProductivity:Month supply capacity of 50000Super Abrasive Resistant Conveyor Belt – Engineered for Extreme Wear and Tear Conditions When it comes to industrial material handling, selecting the right conveyor belt is critical for operational efficiency, safety, and long-term cost savings. Our...

-

Unit Price:USD 14 / MeterBrand:ieTa RubberMin. Order:100 MeterModel No:TT-F005Transportation:Ocean,LandPackaging:Roll packaging,Wooden crate/wooden frame packaging,Palletizing,Special environmental packaging,Bare packaging and simple packagingSupply Ability:500000/㎡Place of Origin:KaiFeng He Nan ChinaProductivity:Month supply capacity of 50000EP300 Abrasive Resistant Conveyor Belt – Durable, High-Performance Industrial Material Handling Solution The EP300 Abrasive Resistant Conveyor Belt is engineered for demanding industrial environments where continuous operation, high tensile...

-

Unit Price:USD 17 / MeterBrand:ieTa RubberMin. Order:100 MeterModel No:TT-F004Transportation:Ocean,LandPackaging:Roll packaging,Wooden crate/wooden frame packaging,Palletizing,Special environmental packaging,Bare packaging and simple packagingSupply Ability:500000/㎡Place of Origin:KaiFeng He Nan ChinaProductivity:Month supply capacity of 50000Good Quality Abrasive Resistant Conveyor Belt – Durable, High-Performance Solution for Heavy-Duty Material Handling When it comes to reliable and efficient bulk material transport in demanding industrial environments, a high-performance abrasive...

-

Unit Price:USD 16 / MeterBrand:ieTa RubberMin. Order:100 MeterModel No:TT-F003Transportation:Ocean,LandPackaging:Roll packaging,Wooden crate/wooden frame packaging,Palletizing,Special environmental packaging,Bare packaging and simple packagingSupply Ability:500000/㎡Place of Origin:KaiFeng He Nan ChinaProductivity:Month supply capacity of 50000NN300 Abrasion Resistant Rubber Belt – Engineered for Heavy-Duty Material Handling in Demanding Environments The NN300 Abrasion Resistant Rubber Belt is a high-performance conveyor solution designed to withstand extreme wear and tear in industrial...

-

Unit Price:USD 13 / MeterBrand:ieTa RubberMin. Order:100 MeterModel No:TT-F002Transportation:Ocean,LandPackaging:Roll packaging,Wooden crate/wooden frame packaging,Palletizing,Special environmental packaging,Bare packaging and simple packagingSupply Ability:500000/㎡Place of Origin:KaiFeng He Nan ChinaProductivity:Month supply capacity of 50000EP1200 Abrasive Resistant Conveyor Belt – Durable, High-Performance Solution for Demanding Industrial Applications The EP1200 Abrasive Resistant Conveyor Belt is engineered for heavy-duty environments where material handling demands exceptional...

1、Overview

Designed to withstand the harshest material handling environments, Abrasive Resistant Conveyor Belts are engineered for transporting highly abrasive materials such as crushed stone, ores, sand, and glass. These belts combine advanced rubber compounds and robust carcass structures to minimize wear, extend service life, and reduce downtime in industries like mining, quarrying, cement production, and recycling. The core performance indicator is abrasion loss, measured in mm³, where lower values signify superior resistance. For example, a belt with an abrasion loss of 150 mm³ outperforms one with 200 mm³ under identical conditions.

2、Key Applications

- Mining & Quarrying: Transporting granite, limestone, and iron ore, where sharp particles cause cutting and gouging abrasion.

- Construction Materials: Handling sand, gravel, and concrete aggregates that act as "mechanical sandpaper" on belt surfaces.

- Recycling Facilities: Conveying broken glass, metal scraps, and rubble with high impact forces.

- Power Plants: Moving coal and ash, which combine abrasion with high-temperature exposure.

3、Material Technology

Cover Rubber Compounds

- SBR (Styrene-Butadiene Rubber): Standard for moderate abrasion, offering good elasticity and cost-efficiency. SBR-based covers typically achieve abrasion loss of 150–200 mm³ (DIN Y/ISO L grade).

- NR/SBR Blends: Enhance impact resistance for heavy loads, suitable for applications like rock crushing where both wear and impact matter.

- Ceramic-Enhanced Rubbers: Incorporate nano-ceramic particles or vulcanized ceramic tiles to reduce abrasion loss to 50–100 mm³ (DIN X/ISO H grade), ideal for extreme conditions like diamond mine conveyors.

- UAR (Ultra-Abrasion Resistant) Compounds: Proprietary formulations (e.g., Bridgestone's UAR) designed for fine, highly abrasive materials like silica sand, with wear life up to 50% longer than standard belts.

4、Carcass Reinforcements

- Polyester/Nylon Canvas: High-tensile fabrics that minimize elongation and support thick abrasion-resistant covers.

- steel cord: For heavy-duty applications, providing up to 5000 N/mm tensile strength and resistance to structural wear from repeated flexing.

5、Technical Specifications

| Parameter | Standard Range | High-Performance Grade | Test Method |

| Abrasion Loss | 150–200 mm³ (DIN Y) | 50–100 mm³ (DIN X) | ISO 4649 / DIN 53516 |

| Tensile Strength | ≥18 MPa (cover rubber) | ≥25 MPa (ceramic-reinforced) | ISO 37 |

| Elongation at Break | ≥350% | ≥400% (flexible designs) | ISO 37 |

| Working Temperature | -25°C to +80°C | -40°C to +100°C (special grades) | EN 12882 |

| Cover Thickness | 3–10 mm (top cover) | 10–15 mm (extreme abrasion) | GB/T 7984 |

| Static Electricity | ≤3×10⁸ Ω (anti-static) | Customizable for hazardous areas | DIN 22102 |

Note: Abrasion resistance varies significantly with material type. For example, belts handling fine cement powder require different compounds than those carrying jagged ore chunks.

6、Product Features & Benefits

(1)Multi-Mode Wear Protection

- Abrasive Wear: Fine particles (e.g., sand) cause surface erosion; addressed by high-hardness rubber (60–75 Shore A) and dense compound structures.

- Cutting/Gouging: Sharp objects (e.g., broken glass) create deep tears; mitigated by ceramic-reinforced top covers with high tear strength (≥30 kN/m).

- Impact Wear: Heavy drops (e.g., ore from crushers) cause internal damage; resolved by flexible carcass designs with shock-absorbing rubber layers.

(2)Performance Optimization

- Self-Cleaning Grooves: Strategic surface patterns prevent material buildup, reducing secondary abrasion in wet conditions.

- Temperature Resistance: Specialized compounds maintain elasticity in high-heat zones (e.g., near kilns), avoiding brittleness and cracking.

(3)Cost Efficiency

- A belt with DIN X abrasion rating (50 mm³ loss) may cost 30% more than a DIN Y belt but can reduce replacement frequency by 70% in severe applications, yielding net savings of 40% over 5 years.

7、Selection Guide

- Assess Material Abrasiveness:

- Light Abrasion: Grains, processed foods (choose DIN Y/ISO L, abrasion loss ≤200 mm³).

- Moderate Abrasion: Sand, coal (opt for DIN W/ISO D, 100–150 mm³).

- Severe Abrasion: Granite, ores (require DIN X/ISO H, ≤100 mm³).

- Consider Operational Factors:

- Loading Point Impact: High drops (≥3 m) need belts with ≥400% elongation to absorb shock.

- Conveyor Length: Short belts (<50 m) wear faster due to more frequent loading cycles—prioritize abrasion resistance over thickness.

- Test Compliance:

Insist on manufacturers providing actual test results (not just standard minimums). For example, a belt claiming compliance with ISO 14890 H should have documented abrasion loss ≤90 mm³, not just meet the 100 mm³ standard minimum.

Abrasive Resistant Conveyor Belt

What is an abrasive resistant conveyor belt?

Performance refers to how quickly site content loaPerformance refers to how quickly site content loads and renders in a web browser.Performance refers Performance refers to how quickly site content loaPerformance refers to how quickly site content loads and renders in a web browser.Performance refers

What materials are usually used to make abrasive resistant conveyor belts?

Performance refers to how quickly site content loaPerformance refers to how quickly site content loads and renders in a web browser.Performance refers Performance refers to how quickly site content loaPerformance refers to how quickly site content loads and renders in a web browser.Performance refers

How is the abrasion resistance of conveyor belts measured?

Performance refers to how quickly site content loaPerformance refers to how quickly site content loads and renders in a web browser.Performance refers Performance refers to how quickly site content loaPerformance refers to how quickly site content loads and renders in a web browser.Performance refers